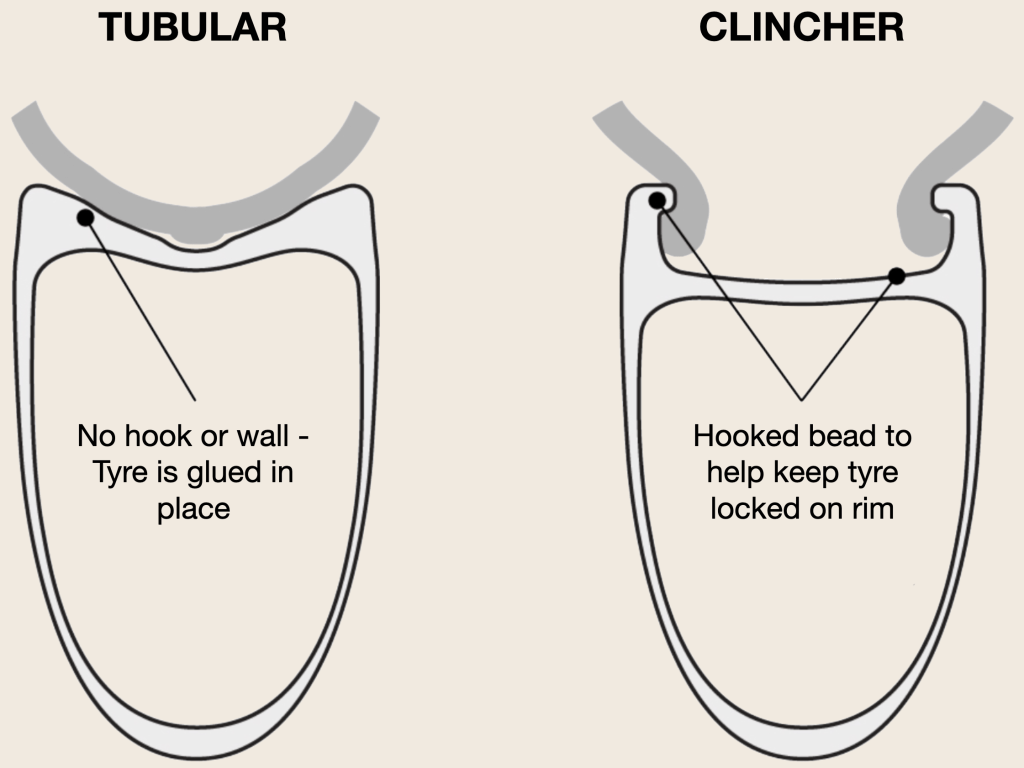

When I bought my bicycles in the early to mid-2010s, the only wheel and tire choice was tubular or clincher. Tubular tyres are glued onto the wheel. Clincher tyres have a bead that fits under hooks on the rim to hold the tyre onto the rim. If punctured, the repair of a tubular tyre can be more challenging, and, in many cases, it’s more feasible to replace it. A clincher tyre has an inner tube which is easy to replace.

Despite the advantages of tubular tyres – lightweight, better ride quality and lower rolling resistance, the choice of tyre for me was a no-brainer. I didn’t want to deal with glueing tyres and carrying a spare tubular tyre when I rode.

In 1999, Mavic introduced the first tubeless tyre for mountain bikes. In 2017, Mavic launched a ‘Road UST’ standard specifying dimensional and pressure requirements. This standard was then used by the European Tyre and Rim Technical Organisation (ETRTO) to develop road tubeless standards that were implemented in 2019.

There are three choices of non-tubular tyre and wheel combinations today. Clincher with tube, tubeless with hooks and tubeless hookless. Hookless rims are the most recent innovation in road cycling wheels. The ETRTO set standards for hookless rims in 2019.

The debate about whether to go tubeless is a lively one. There is no doubt about the benefits of road tubeless. As compared to tubed clincher tyres, tubeless systems offer:

- Lower tyre pressures

- Greatly reduced risk of puncturing

- Repair options

- Lower rolling resistance

- Less weight

Tubeless tyres come with drawbacks as well:

- Require compatible wheels

- Can be difficult to install

- Require sealant

- Punctures can be messy

- Require regular maintenance

- Expensive

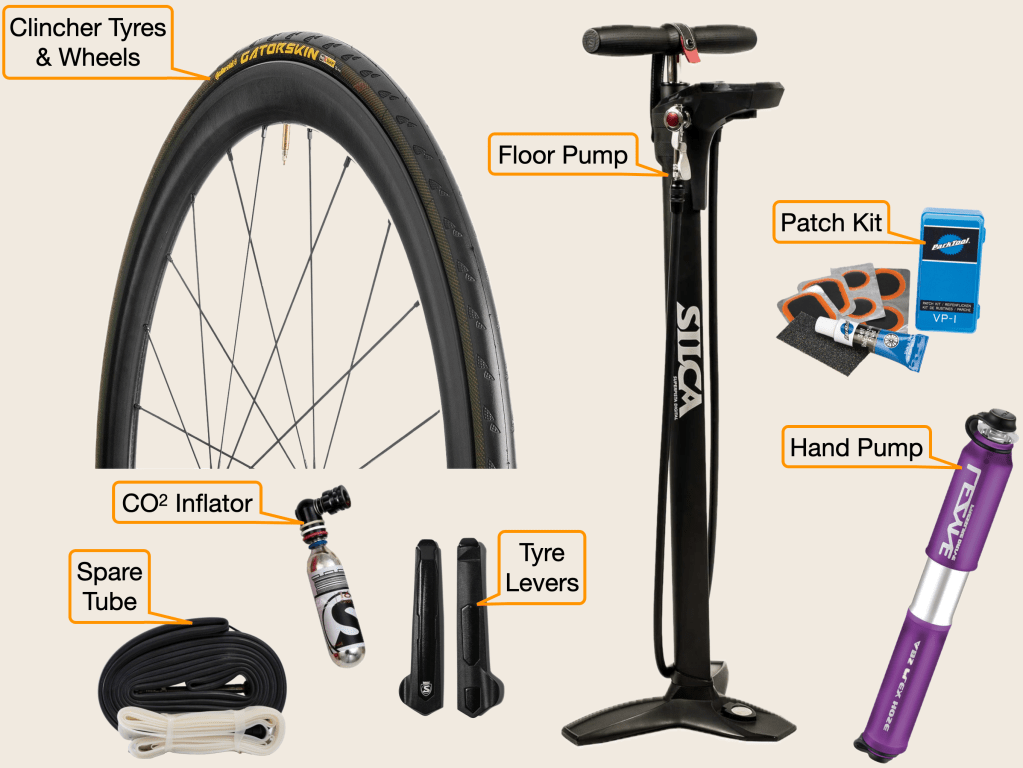

I still ride on clinchers. I don’t get many punctures and am happy to change an inner tube when I do. I don’t ride fast enough for lower rolling resistance and weight to make a difference. For me, the disadvantages of road tubeless outweigh the advantages.

Someone switching to road tubeless tyres would require most, if not all, of the items below. I suggest tubeless rather than tubeless-ready wheels. Tubeless wheels do not require rim tape. Choose tyres that are on the wheel manufacturer’s compatible tyre list. An incompatible tyre might roll off the rim, potentially causing injury or even death. A tyre that is the right size for the rim may negate the need for tyre mounting pliers. Seating a tyre in a rim will require a high-pressure pump. Despite sealant in the tyres, pack a spare tube and a high-pressure pump or CO2 inflator in case a puncture is too large for a plug to repair.

Apart from the carbon rims (I ride on alloy rims), the items below are the exact items I use to keep my bicycle wheels rolling. The Continental Gatorskins are not the lightest tyres but the PolyX Breaker™ cut and puncture-proof layer is worth the extra 115 grams over the Vectran™ Breaker layer in a Continental Grand Prix 5000 tyre. The only maintenance these tyres need is an occasional top-up of air using my Silca Superpista floor pump.

A challenge to greater acceptance of road tubeless tyres is the level of confusion around which tyres can be used with which rims. The ETRTO road tubeless standards act as a guideline for rim and tyre manufacturers, but there is no law forcing manufacturers to adhere to these standards. This is especially problematic with hookless rims.

Earlier this month the Union Cycliste Internationale (UCI) issued a statement stating it is investigating “recent incidents” involving hookless rims and tubeless tyres “as a matter of urgency… in the interest of rider safety” following Thomas De Gendt’s crash at the UAE Tour in March 2024, which saw his 28mm-wide Vittoria Corsa Pro TLR road tyre blow off a Zipp 353 NSW wheel, which uses hookless rims.

For those wanting the benefits of road tubeless tyres and especially hookless rims, there is hope for the technology to become much more accessible and easier to use as the industry agrees on new standard guidelines. The use of road tubeless tyres may one day match the almost 100% acceptance of tubeless tyres for mountain bikes, where tubeless compatibility is mostly straightforward.

My issue with road tubeless tyres is the hassle sealant brings. Sealant oozing through sidewalls. The potential for spills when pouring sealant into the tyre. Sealant spraying out through a puncture. The need to remove dry sealant from inside the tyre and valve.

There is a new tyre on the market that may address these issues. The Hutchinson Challenger TLR. This tubeless tyre is designed to run without sealant.

Hutchinson’s HARDSHIELD™ technology provides puncture protection. Their AIRSHIELD™ technology ensures the tyre is airtight.

The Challenger TLR is an all-season tyre that apparently offers better ride quality than the Gatorskins I use now. At about €60 / MYR300 the Challenger TLR is not a cheap tyre. Nevertheless, when my clincher tyres need replacing I may take the plunge into the road tubeless world with the Hutchinson Challenger TLRs.

Good article. The above information is sufficient to decide that tubless road tire setup is only practical when a small performance gain is needed to be competitive. Tubless still gets flats – but unless you are good at using a “dart” to plug the puncture , you will still be dealing with a flat in a competitive gravel race ( example ) …the puncture needs air pressure to ‘self seal’ and rotation of the wheel to seal. Probably changing a tube and using a Co2 is still a slower flat fix. Tubless is not for casual riders.

Pingback: I Wouldn’t Want to Service a Modern Road Bike | Old Roots, New Routes